Example: X0 G84 Z Example: X G72 - Facing Cycle. Note this might not work on every lathe or machining centre so the following method has been included. It is followed by the G70 finishing cycle. The G73 cycle is a pattern repeating roughing cycle used in boring or turning. It works the same as the G71 cycle but is used to remove material by cutting along the X-axis. It is used to remove material by cutting along the Z-axis leaving some material on for a finishing cut using a G70 cycle. The G71 roughing cycle follows the contour that is programmed between the N numbers. The'P' and 'Q' values are used to locate the profile in that cycle and run a finishing cut that follows it. Example: G00 X This cycle is used after one of the roughing cycles and follows the contour programmed within that roughing cycle. The control system will understand the operation and perform the repetitive cycle following the commands that are given by the programmer until the feature is complete.

#Mastercam 2019 drill deeper code

G84 tap cycle is one of the mostly used function of CNC machining centers.R epetitive cycles are used in CNC Lathe Programming to minimise the amount of code that has to be written and give us more control over complex shapes and operations. Here is a cnc programming example for simple drilling on a cnc lathe machine. Tapping with Fanuc G74 tapping cycle is performed…. CNC Torna Tezgahlarında G83 Delik Delme Çevirimininde Kullandığını Biliyor muydunuz ? G82 is a normal drilling cycle the only difference is that it dwell for specified time at the bottom of….

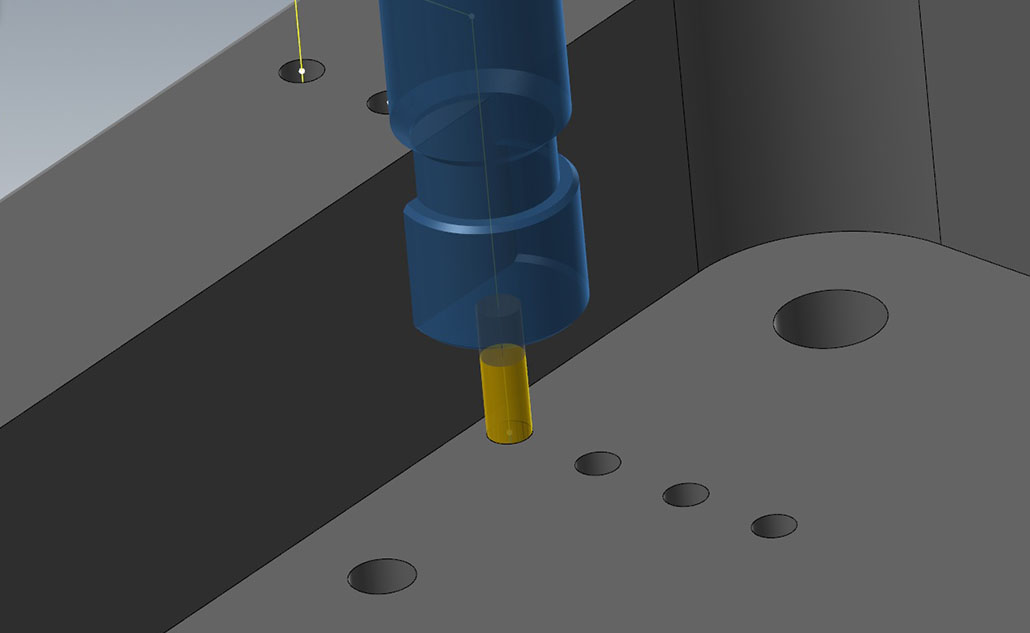

G82 drilling cycle is also called G82 counter boring cycle. To make such deep hole tapping operations….Ī complete cnc part-program which shows how G98 and G99 canned cycle return level work with G81 drilling cycle and G83 peck drilling cycle for drilling of a component which…. Tapping a deep hole in rigid tapping mode may be difficult due to chips sticking to the tool tap or increased cutting resistance. So the standard G84 tapping cycle can be used for repeat tapping the same hole or multiple holes…. Haas CNC machining centers allows to repeat rigid tapping operation with accuracy. G83 deep hole peck drilling cycle makes the drilling of deep holes a breeze. G83 peck drilling cycle perform the drilling operation in multiple pecks, this technique makes deep-hole drilling easy and economical.Ĭutting feed is performed intermittently to the bottom of the hole….

#Mastercam 2019 drill deeper full

Siemens Sinumerik CYCLE83 Peck drilling cycle makes deep hole drilling easy, Very flexible drilling cycle gives cnc machinists full control over all aspects of deep hole drilling tasks. The tool will take the peck Q deep Then the tool will rapid up to the R plane after each peck and then back in for the next peck until Z depth is reached. This cnc program example explains the use of G81 Drilling cycle but this time the tool is not positioned in the usual way G90 absolute programming mode but this time….As G83 is a Peck drilling cycle so the depth for each peck in G83 drilling cycle will be the amount defined with Q.

This G84 tapping cycle example program illustrates the use of tapping in an easy to understand…. G84 tap cycle is one of the mostly used function of CNC machining centers. A complete cnc part-program which shows how G98 and G99 canned cycle return level work with G81 drilling cycle and G83 peck drilling cycle for drilling of a component which….

To make such deep hole tapping operations…. That specified distance is defined in Setting Siemens Sinumerik CYCLE83 Peck drilling cycle makes deep hole drilling easy, Very flexible drilling cycle gives cnc machinists full control over all aspects of deep hole drilling tasks.ĬNC machinists…. Setting 22 - As the tool pecks deeper into the hole, with each peck it rapids out to the R-plane, and then back in to a constant specified distance above the bottom of the hole that was created by the previous peck.

0 kommentar(er)

0 kommentar(er)